Safety Valves

Our Valves are produced according to International ASTM ANSI Standards, ASTM API Standards, and ASTM DIN Standards in India.

Product description

To prevent the uncontrolled rise in pressure in pressure vessels or pressurized pipelines, a safety valve is inserted. The safety valve is designed so that it opens at given maximum pressure, thereby relieving the line or the container. Safety valves find their use in almost all areas of pressure vessel and pipeline construction. In cryogenics as a spring-loaded safety valve for example.

Ultimate safety is the aim of our development and production. This is especially when the safety of people is at stake. Because of this, we test the reliability of our products in especially extreme situations.

Characteristics

A Safety Valves is a Valves that acts as a fail-safe. An example of Safety Valves is a pressure relief valve, which automatically releases a substance from a boiler, pressure vessel, or another system when the pressure or temperature exceeds preset limits.

Spring Loaded Safety Valves with Lever

Characteristics: Fire safe design, High-Pressure Rating, Inspected, and Quality Tested.

Spring Loaded Safety Valves with Cap

Characteristics: Fire safe design, High-Pressure Rating, Inspected, and Quality Tested.

Specifications

Size: 1/2” X 1/2” to 2” X 2” | Screwed end, Butt Weld End

1 X 2” to 12” X 16” | Flanged End, Butt Weld End

Ratings: 150# X 150# to 2500# X 300#

Blow Down Pressure: 10% Less Than of The Set Pressure

Hydrostatic Test Pressure: 1.5 Times The Set Pressure

Overpressure: 10% Of The Set Pressure

Orifice Designation: As per API

Application: Air, Gas, Liquid

Materials: WCB, WC1, WC6, WC9, LCB, LCC, LC3, C5, C12, CF8, CF8M

Design

Design Standard: API 520

Performance Standard: API 526

Seat Tightness Test: API 527

Features

- Spring Loaded Safety Relief Valve

- Full Lift Pop Action Design and Open Bonnet with Lever

- Stellated Nozzle & Disc Seating Area

- Soft Seat with P.T.F.E., Peek & Viton

- Balance Bellows Type Safety Relief Valve

Advantages and applications

The most important benefits of utilizing Safety Valves are the full bore for the flow media, and 100% airtight shut off – even on solids such as granules, powders, pellets, chippings, fibers, slivers.

Safety Valves Application:

· Petrochemical.

· Refining

· Power.

· Pulp and Paper.

· Oil and Gas, Sugar.

· Hospitals.

· Colleges.

Safety Valve's Functions

Safety Valve’s Function:

“Nozzle” inside the Safety Valves begins to obtain a higher pressure from the inlet side of the valve.

When the pressure becomes higher than the set pressure, “Disc” starts to lift and discharge the fluid.

When the pressure reduces until the set pressure, the force of the spring closes “Disc”.

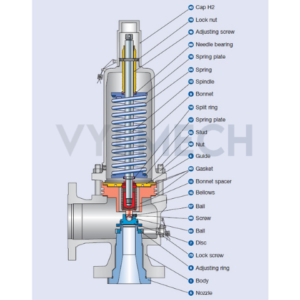

Role of the spare parts.

Nozzle – Pressure Entrance

Disc – Lid

Spring – Pressure Controller

feel free to connect

We might work together and might start a trustworthy work relationship for a long time.