Ball Valves

Our Valves are produced according to International ASTM ANSI Standards, ASTM API Standards, and ASTM DIN Standards in India.

What are Ball valves?

A globe valve, different from other Valves, is a type of Valves used for Controlling flow in a pipeline, Constructed of a movable disk-type element and a stationary ring seat in a generally spherical body.

A Globe Valves is a direct motion Valve and are essentially designed to stop, start and adjust flow. The disk of a Globe Valves can be removed from the flow path or it can effectively block the flow path.

Product description

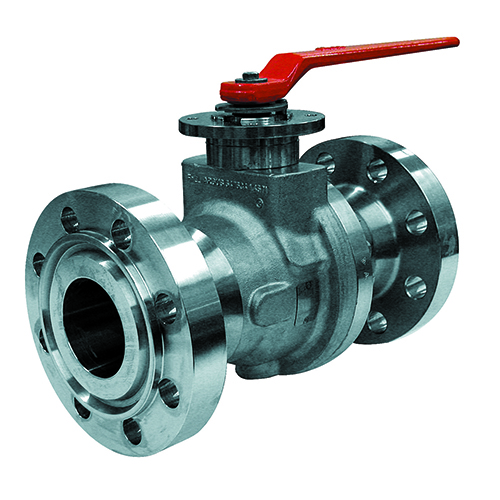

A Ball Valve is a kind of quarter-turn valve which utilizes a hollow, perforated, and pivoting Ball to manage flow into it. It is open when the ball’s hole is in series with the flow and closed when it is swiveled 90-degrees through the valve stem. The handle sprawls even in order with the flow when open, and is perpendicular to it during its closure, making for smooth visible evidence of the valve’s situation.

Product Materials

- Bronze (CAC401, CAC406)

- Brass (C3771)

- Gray cast iron (FC200, FC300)

- Ductile iron castings (FCD-S)

- Carbon steel castings for high temperature/pressure service (SCPH 2)

Product features

Ball Valves are hard-wearing, functioning adequately after numerous circles, and strong, locking securely indeed after extended years of decay. These characteristics make them an outstanding opportunity for shutoff and control purposes, where they are often preferred to gates and Globe Valves, but they lack their precise control in throttling utilization.

Ball Valve's Applications

Vylmech Engineering Pvt Ltd.’s Ball valve’s smoothness of development, improvement, and flexibility allows it to widespread technical control, enduring pressures up to 1000 bar and temperatures up to 752 °F (400 °C), depending on the design and raw materials utilized. Sizes typically vary from 0.2 to 48 inches (0.5 cm to 121 cm). Valve assemblies are made of metal, plastic, or metal with a ceramic floating ball are frequently chrome plated for strength. One limitation of a Ball valve is that they confine water in the center cavity while in the sealed environment. In freezing environments, the sides can break due to the extension of ice forming. Some means of protecting or heat tape in this situation will usually prevent damage. Another option for this condition is the “freeze sophisticated Ball valve”. This form of Ball valve combines a freeze plug in the side so in the case of a freeze-up, the freeze plug cracks (performed as a sacrificing disk), thus preparing for an uncomplicated repair. Presently instead of reinstating the entire valve, just screw in a fresh freeze plug.

feel free to connect

We might work together and might start a trustworthy work relationship for a long time.