Audco Valves

You are here: Brands / Audco Valves

Audco Gate Valve

The valves come in a range of construction materials, with flanged ends or butt-weld ends, pressure ratings ranging from ASME Class 150 to Class 1500. Gate Valves are constructed with a flexible wedge, an outer screw and yoke, and a bolted-bonnet. The valves are API 600 compliant.

Audco Globe Valves

The valves come in a range of construction materials, with flanged ends or butt-weld ends, pressure ratings ranging from ASME Class 150 to Class 1500. Globe Valves are made with a bolted-bonnet construction, an outside screw and yoke, and a ball-type disc. They comply with BS 1873 and, in terms of stuffing box dimensions and shell wall thickness, also satisfy API 600’s general specifications.

Audco Check Valves

The valves are offered with butt-weld ends or flanged ends, in pressure ratings ranging from ASME Class 150 to Class 1500, and in a number of construction materials. Globe Valves have an outside screw and yoke, a bolted-bonnet design, and a ball-type disc. They meet the main specifications of API 600, including the shell wall thickness and stuffing box dimensions, and they also comply with BS 1873.

Audco Butterfly valve

Global recognition for the high calibre, dependability, and longevity of AIL Forged Steel Gate, Globe, and Check Valves. These valves are rugged and compact in design, produced to the most recent international standards using cutting-edge manufacturing techniques and rigorous quality control inspections. Major Indian and worldwide clients, such as oil refining corporations and EPC contractors, are regularly supplied with the valves. For reduced-bore designs, they come in a variety of sizes ranging from 1/4″ to 2″; for full-bore designs, the sizes range from 3/8″ to 11/2″.

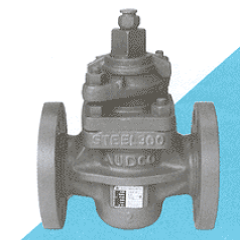

Audco Plug Valve

The Audco Taper Plug Valve is utilised in a wide range of liquid, gaseous, and slurry services. It is manufactured in sizes ranging from 12″ to 12″. Although the tapered plug is firmly secured in its tapered seat, it can be adjusted to achieve complete leaktightness and smooth valve operation. When the valve is in the open position, the tapered seating surfaces of the plug and body are not exposed to the line fluid, limiting the effects of corrosion and erosion to the valve’s less crucial components. Additionally, because of the straight flowpath through the valve, there is minimal pressure loss and very little flow resistance.

Audco FORGED STEEL valve

The valves come in a range of construction materials, with flanged ends or butt-weld ends, pressure ratings ranging from ASME Class 150 to Class 1500. Check Swing-type valves have a bolted cover construction. They meet the main standards of API 600, including shell wall thickness, and are compliant with BS 1868.

Audco FLOATING Ball Valve

Both floating and trunnion mounted ball valves are produced by AIL. In order to create a tight seal, the floating-ball design of the conventional AIL Ball Valve allows the ball to travel towards the downstream seat while under pressure. The majority of industrial and utility applications favour the floating ball design.

Audco TRUNNION-MOUNTED BALL Valve

Industry prefers trunnion-mounted ball valves for larger sizes, greater pressure ratings, and unique services that need double-block and bleed features. By enabling the seat to move in the direction of the ball along the flow axis, sealing is accomplished in this arrangement. Trunnion-mounted ball valves are made by AIL in a wide variety of styles, including welded joint and bolted body joint designs. These valves are available with soft seats for crucial process applications and metal seats for cross-country pipeline applications.

feel free to connect

We might work together and might start a trustworthy work relationship for a long time.