Plug Valves

Our Valves are produced according to International ASTM ANSI Standards, ASTM API Standards, and ASTM DIN Standards in India.

Product description

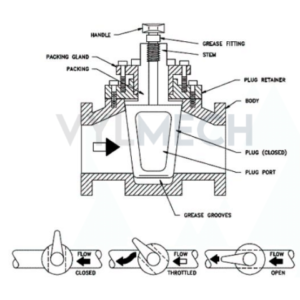

Formed like a cone or cylinder, a Plug Valves utilizes a rotating plug inside the body of a Valves to regulate fluid flow. These varieties of Valves have one or more horizontal ways to permit flow within the Valves when open. Plug Valves are usually used to transfer liquids or gases. They typically have two ports but can also have three or more depending on the purpose.

Specs & Characterization

Design and Manufacturing of Plug Valves:

API 599: Metal Plug Valves – Flanged and Welding Ends

API 6D: Pipeline Valves. Pressure Test Specification.

Characteristics:

- Fire-safe design.

- Thoroughly Inspected.

- High-Pressure Evaluation.

- Quality Examined.

The most significant perks of utilizing Plug Valves are the full bore for the flow media, and 100% sealed shut-off – even on solids such as granules, powders, pellets, chippings, fibers, slivers.

Inspections and Examinations:

API 6D: Pipeline Valves. Pressure Test Specification.

API 598: Valve Inspection and Testing

ISO 15848: Industrial Valves – Measurement, test, and qualification procedures

for fugitive emissions.

Welded or Threaded ends:

ASME B16.25: Butt-welding ends.

ASMEB16.11: Forged fittings, socket-welding and threaded

ASME B1.20.1: Pipe threads general purpose.

Key Features

- Prompt low-torque quarter-turn actuation

- PTFE-coated plug produces low operating torque

- Compact one-piece body and Simple maintenance

- Pipe end connections

- Obtainable in 316 Stainless Steel and Brass

- Vented Valves are available

- One-piece stainless steel handle and plugs are available

feel free to connect

We might work together and might start a trustworthy work relationship for a long time.